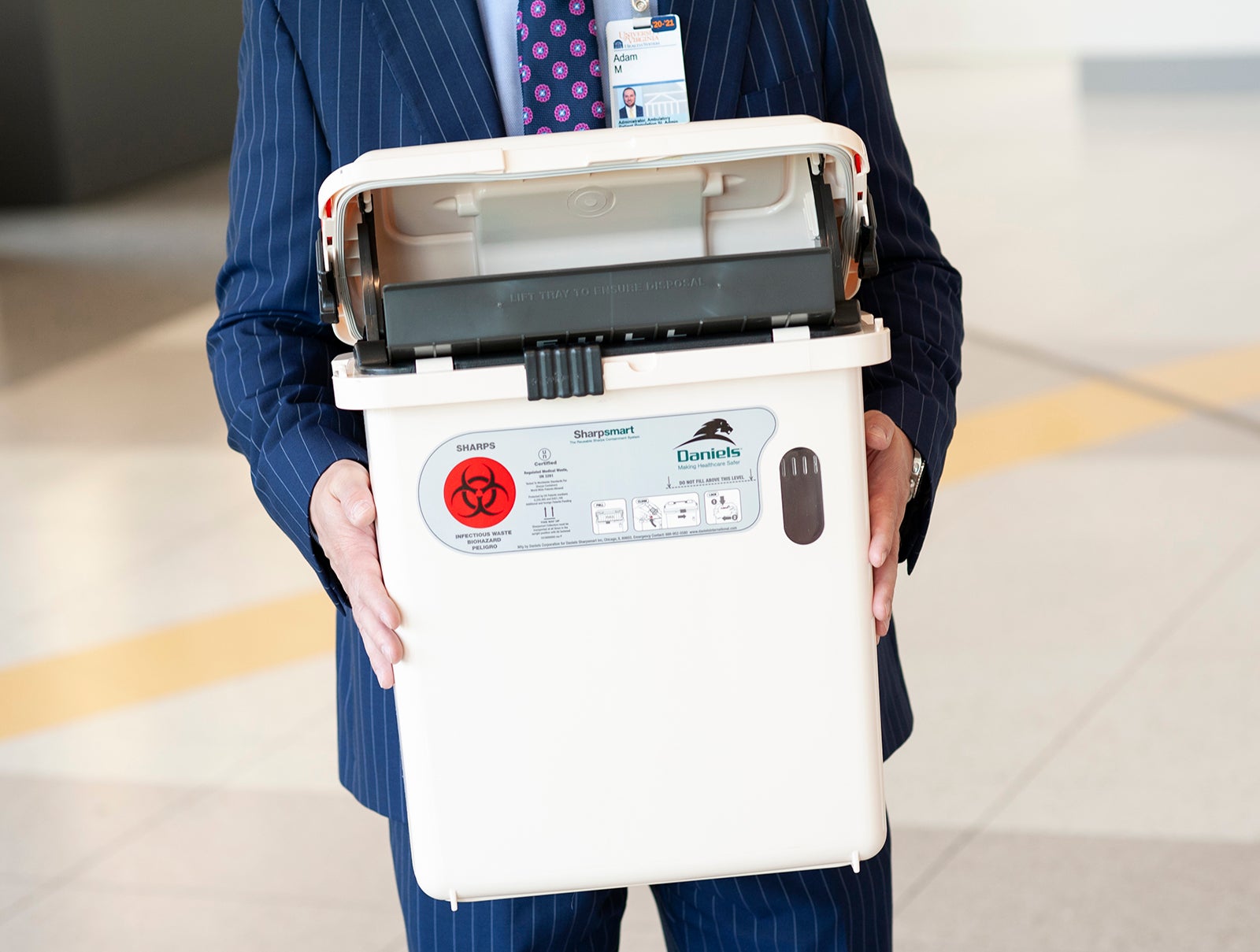

Supply Chain Administrator Adam Momper (center) flanked by Jody Farmer, RN (left), and Heidi Ross, RN (right). While there were many team members who were instrumental in the rapid deployment of these new sharps boxes, Project Lead Michael Payne credits the success of the installation in part to Jody and Heidi's efforts. "They were incredible to work with. They made a difficult set of circumstances not only pleasant but productive!" (Photos by Kay Taylor)

Have You Seen Our New Sharps Boxes? Here’s the Success Story Behind Them

This is going to be a bad news, good news story. First, the bad news: a devastating fire at a resin factory in China caused a supply shortage. For us, the shortage meant running out of the red-and-yellow boxes that hold used sharps in University Hospital, Emily Couric Clinical Cancer Center, and the Battle Building.

Here’s the good news: We are now using environmentally friendly, reusable sharps boxes. They were installed so quickly that our new supplier’s transition team dubbed it “the best planned and implemented” conversion in an organization of our size. In all, 2,000 sharps boxes were swapped out in less than two weeks.

Key Elements of Our Success

- Planning and Foresight: Approximately 18 months before the shortage began, the Sharps Safety Coalition recommended we switch to reusable containers to reduce biohazard waste. A cross-functional team, the Sharps Safety coalition oversees our Sharps Injury Prevention program. Over the years, the coalition has worked to prevent needlesticks and sharps injuries through continuous improvement and introducing safer ways to handle sharps.

- Collaboration: Supply Chain Administrator Adam Momper, says the super-fast swap out was made possible by proactive communication and collaboration among many groups — nursing, Supply Chain, Value Management & Analysis, Infection Control, the Sharps Coalition, and Facilities Management.

- Strong Project Leadership: Momper credits project lead Mike Payne from Value Management for the swap out’s success.

Looking Toward the Future

According to Momper, the sharps box conversion is a shining example of how the Supply Chain work group is helping to achieve Bridge Plan goals. “We’re looking to create a clinically led supply chain,” he explains. “The kind of collaboration and partnership exhibited during the sharp box project will be essential as we pursue a bevy of initiatives over the next fiscal year to drive clinical quality, increased product standardization, and cost savings.”

Learn more about the Bridge Plan here.

Latest News